Equipment

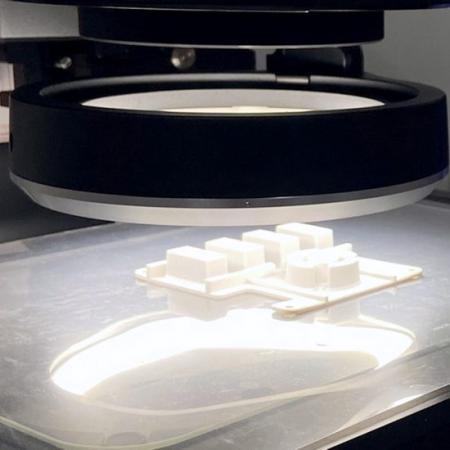

The production equipment of Jan Huei includes vacuum compression molding, solid injection molding, liquid injection molding. Generally, the vacuum compression molding is a popular molding method. It has the advantages of being able to undertake a small amount of production (MOQ: 1000pcs), rapidly exchange color, and cheaper mold development costs. However, its disadvantages are lower productivity and obvious parting lines. Therefore, the simple structure of products such as silicone gasket, seal, grommet, silicone keypad or a small amount of silicone products, customers will consider the vacuum compression molding to save production costs.

There are two types of injection machines: solid injection and liquid injection. Injection molding has better productivity than vacuum compression molding, and the parting line is more detailed. In addition, the silicone is not exposed to the environment for a long time, so the defective rate of the injection molding is low. The disadvantage of injection molding is high production demand (MOQ: 100K) and it takes a lot of time to change the color of silicone. Therefore, it is suitable for injection molding if the product with high demand and high quality.

Inspection Equipment

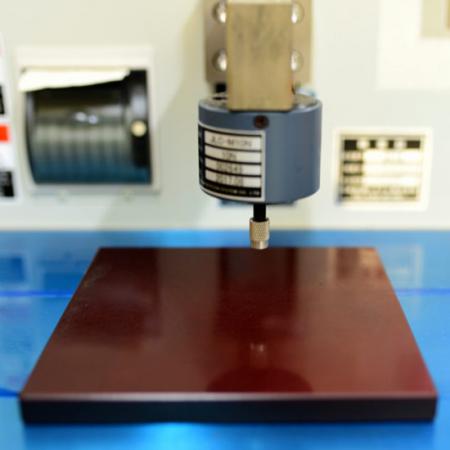

In the inspection equipment, we have automatic / semi-automatic 2.5D image dimension measurement equipment, load testing machine, life tester, spring testing machine, RCA tester and tensile tester. In recent years, customers have increased their quality requirements. Therefore, Jan Huei has purchased automatic 2.5D optical measurement equipment to measure amounts of specification in batches in order to increase efficiency and accuracy.

Load testing machines and spring testing machine are usually used for silicone keys. The maximum load of the load test is 1KG; spring testing machine can detect the resilience and load of the key. The life tester is only used to test the life of the keys, and provides accurate usage times.

From materials, molding, quality control, inspection to shipment, our core philosophy is to maintain a stable schedule and maintain good quality.

Our Equipment

- 2.5D Image Dimension Measurement Equipment

- Load Testing Machine

- Membrane Keyboard Tester

- Life Tester

- Abrasion Tester

- Hardness Tester

- Ohmmeter

- Electrostatic Tester

- Vacuum Compression Machine

- Injection-Molding Machine

- Mixer

- Mixing Mill

- Microscope

- Tension Machine

- Liquid Silicone Rubber Injection Molding Machine

- 2.5D Image Dimension Measurement System