Silicone Seal Combined with differeial material

Silicone Rubber seal

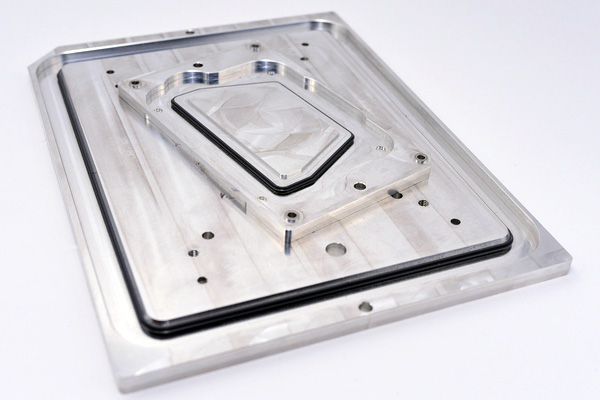

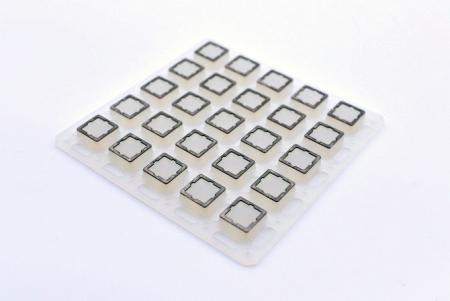

Silicone seals combined with differential materials can be customized to meet your specific needs, with sizes available up to 400mm. We offer both compression molding and injection molding methods to achieve the desired results for your project. Our silicone seals are designed to improve surface friction and provide air tightness, making them ideal for a variety of applications. For example, the back cover is composed of an aluminum alloy plate and a silicone seal, manufactured using solid silicone injection molding to ensure optimal performance. We continually improve our manufacturing process and mold design to deliver a burr-free finish. Contact us Jan Huei today to learn more about how we can customize a silicone seal solution that meets your needs.

Not only aluminum alloy materials, plastics, magnesium alloys, iron plates, and glass can combine with seals in a similar design.

Key Features and Benefits

- SHORE A 45°.

- Material Characteristics: HTV, Heat-Resistance, Vibration Absorption

- Material passed by RoHS (Restriction of Hazardous Substances Directive).

Specification

- Molding: Silicone Injection Molding, Silicone Compression Molding

- Size: Maximum Size 400mm

- Color: Customized

- Material: Aluminum Alloy (Magnesium Alloys, Iron) and Silicone

- Effective Cases

- Related Products

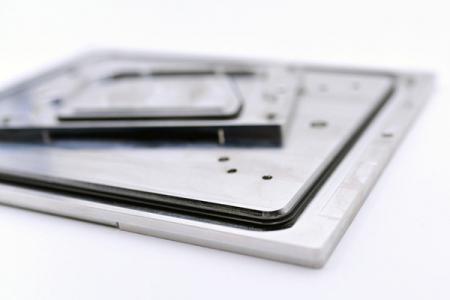

Silicone Combined with Glass

The silicone seal applied to the glass panel can add a waterproof function to it. The silicone rubber is combined with the glass panel tightly by inserting molding. It could achieve the anti-dust and waterproof effect. Jan Huei is an expert on LSR molding technology to produce silicone seals. Considering the type of production, as the same structure, LSR injection molding could enhance production yield by 50-80% more than compression molding. It also could save assembly costs and increase production capacity. Therefore, most customers start to choose this kind of production way to produce a waterproof product.

Silicone Combined with Plastics

Combine silicone and plastic (PC) to produce the customized silicone product by our professional technicians. The waterproof silicone ear-hook headphone is made by Jan Huei and has a size of 80mm x 40mm. The body of the earphone is plastic, which provides strong rigidity and protects the internal wires. The skin-friendly part is made of medical-grade silicone, which can make it waterproof and increase wearing comfort.

Silicone Rubber Combined with Metal

Silicone rubber combined with metals such as steel, aluminum, brass, and other metals can strong structures for silicone products. Some kinds of customers have specific protective requirements like increasing the strength of silicone pads to keep inside electronic products safe. For example, a crash pad uses silicone to protect the parts from impact damage, metal parts can avoid deformation. Our products with silicone metal bonding are heat and UV-resistant.