-

Customized Silicone Wristband

At Jan Huei, we manufacture customized silicone wristbands that provide unmatched comfort, durability, and safety. Our wristbands are crafted from medical-grade and food-grade silicone, making them waterproof, abrasion-resistant, and perfect for sensitive skin.

-

Silicone Diaphragm of Stethoscope

At Jan Huei, we offer high-performance silicone diaphragms for stethoscopes, meticulously engineered to improve diagnostic accuracy. With less than 0.5mm in thickness, our lightweight diaphragms deliver superior sound transmission, making them the preferred choice for healthcare professionals seeking clarity and comfort in auscultation.

-

Silicone Mask & Silicone Nozzle of Nasal Aspirator

At Jan Huei, we specialize in the production of medical-grade silicone masks and silicone nozzles for nasal aspirators, meticulously designed to meet the highest safety and performance standards. We collaborate with leading medical equipment manufacturers to ensure that our custom silicone products provide both superior usability and patient comfort, making them ideal for healthcare applications such as inhaled corticosteroids and nasal aspirators.

-

Silicone Accessories of Artificial Ocular Tonometer

The silicone accessories of the artificial ocular tonometer, developed by Jan Huei and produced in collaboration with a medical device company, are known for their elasticity and resilience. The special structure of the silicone cover allows for pressure testing, with a size of Φ 20mm x 20mm and made from different types of silicone rubber that can handle varying loading capacities. Additionally, the medical-grade silicone used in the cover is skin-friendly and safe for use.

-

Silicone Goggle for Medical Equipment

At Jan Huei, we manufacture customized medical silicone goggles designed to meet the stringent requirements of the healthcare industry. Our goggles combine the strength of plastic and glass fiber frames with the softness and biocompatibility of medical-grade silicone, ensuring comfort and protection. These goggles are tailored to the specific needs of our clients, offering enhanced safety and functionality for use with operating equipment and other medical applications.

-

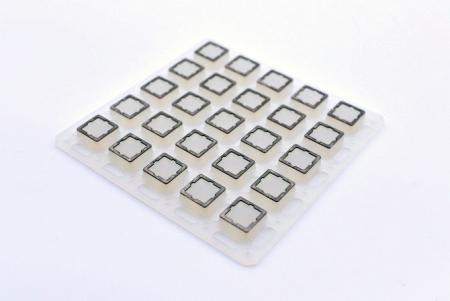

FPC with Silicone

FPC with silicone allows for moderate bending and easy accommodation in the hardware groove, enhancing the convenience of using USB. Furthermore, the substitution of hard plastic with soft silicone further boosts the flexibility and durability of the USB. Jan Huei assist you in creating the perfect silicone product that caters to your unique requirements.

-

Silicone Protective Case

Silicone protective cases combined with different materials can increase the strength of the force, such as barcode scanner case which size is 170mm x 55mm x 40mm. It is silicone combined with a plastic buckle; its inner layer has mesh silicone structure to absorb vibration; its outer layer of silicone has anti-skidding and comfortable handle.

-

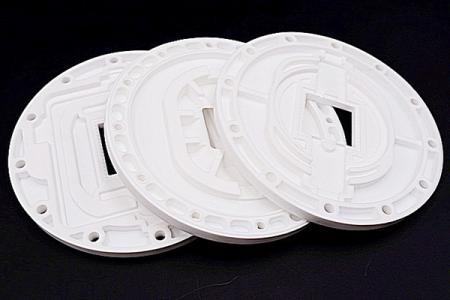

Silicone Seal Combined with differeial material

Silicone seals combined with differential materials can be customized to meet your specific needs, with sizes available up to 400mm. We offer both compression molding and injection molding methods to achieve the desired results for your project. Our silicone seals are designed to improve surface friction and provide air tightness, making them ideal for a variety of applications. For example, the back cover is composed of an aluminum alloy plate and a silicone seal, manufactured using solid silicone injection molding to ensure optimal performance. We continually improve our manufacturing process and mold design to deliver a burr-free finish. Contact us Jan Huei today to learn more about how we can customize a silicone seal solution that meets your needs.

-

Silicone Combined with Plastics

Combine silicone and plastic (PC) to produce the customized silicone product by our professional technicians. The waterproof silicone ear-hook headphone is made by Jan Huei and has a size of 80mm x 40mm. The body of the earphone is plastic, which provides strong rigidity and protects the internal wires. The skin-friendly part is made of medical-grade silicone, which can make it waterproof and increase wearing comfort.

-

Silicone Combined with Glass

The silicone seal applied to the glass panel can add a waterproof function to it. The silicone rubber is combined with the glass panel tightly by inserting molding. It could achieve the anti-dust and waterproof effect. Jan Huei is an expert on LSR molding technology to produce silicone seals. Considering the type of production, as the same structure, LSR injection molding could enhance production yield by 50-80% more than compression molding. It also could save assembly costs and increase production capacity. Therefore, most customers start to choose this kind of production way to produce a waterproof product.

-

Optical-grade LSR Lens

The optical-grade silicone material can reach 95% light transmittance, so it is suitable for making silicone lenses with high transparency. The light transmittance of ordinary silicone material is only 75%, so the finished silicone product after molding will show semi-transparent color. The difficulty and molding conditions for making optical-grade silicone parts are stricter than those for general silicone parts, whether it is in terms of mold, raw material hardness, raw material life, and other conditions. Because optical-grade silicone parts are special, the minimum per batch is more than 20 kg.

-

Silicone Rubber Combined with Metal

Silicone rubber combined with metals such as steel, aluminum, brass, and other metals can strong structures for silicone products. Some kinds of customers have specific protective requirements like increasing the strength of silicone pads to keep inside electronic products safe. For example, a crash pad uses silicone to protect the parts from impact damage, metal parts can avoid deformation. Our products with silicone metal bonding are heat and UV-resistant.

-

Silicone Handle

Silicone rubber is combined with different material parts to produce various styles of handles according to the function of silicone products. The length of the Jan Huei customized handle is about 100mm to 300mm, and the largest size we can customize is about 400mm. Silicone has elasticity, which can not only reduce the discomfort of lifting but also increase the strength of the handle. Through a special production method, we can enclose soft or hard materials in the silicon handle, which is why Jan Huei has won the trust of customers.

-

Silicone Rubber Seal

Silicone rubber seals can be customized in any shape to meet customers' specific needs. The application of silicone seal is wide, we can see seal range from precision parts to industrial machines. You can place the silicone seal in the grooves or gaps of the mechanical equipment to fit on the surface of the mechanical equipment to achieve airtightness and prevent wear. We can provide many styles of silicone seals, such as O-rings, X-rings, Y-rings, C-rings, V-rings, and star-shaped seals with colors, hardness, and so on. They are all resistant to extreme temperatures, UV, and ozone exposure.

-

Silicone Telescopic Tube

Customize the silicone telescopic tube and offer custom lengths of the tube in any size customers want by using compression molding or injection molding process. In this example, we use compression molding to manufacture the silicone telescopic tube and use silicone rubber to meet environmental protection. In case, you need materials with better weather resistance and abrasion resistance, we can choose EPDM to manufacture the silicone telescopic tube. The tube of mechanism in the optical telescopic is most important for dustproof and waterproofing. Because the mechanism is covered with electronic components to control the movement of the lens, the silicone telescopic tube could protect the mechanism avoid to dust being attached and damaged when the lens moves.

-

Thermal Insulator Pad

Thermal insulator pads are products that use heat insulation materials with weather resistance and excellent heat insulation properties. They are typically used as thermal insulation materials for electronic products, industrial metals, medical instruments, and daily necessities. Silicone thermal insulation pads are commonly used in daily household items, such as silicone coasters and silicone potholders

-

Silicone Strips

Silicone strips are not only widely used in life but also used in the technology industry, such as temperature-resistant silicone strips, which are used as an intermediate material to isolate high-temperature semi-products. Most silicone strips are extrusion molding and have the advantage of high productivity. Through the silicone extrusion molding, the tolerance of the polygon can be controlled at 0.25mm. Because of the multi-application of silicone strips, Jan-Hui provides customized production of the shape and size of silicone strips.

-

Silicone Plug

Silicone rubber plugs can be molded by compression molding or injection molding process, which can withstand high temperatures. The waterproof plug is made of silicone or rubber commonly. The advantages are as follows: First, the price is cost-effective. Second, silicone rubber or rubber has good deformation ability and is superior to other materials in filling the gap. Third, weather resistance and aging resistance are better than plastic. In case of a special environment such as oil or chemical, we recommend choosing rubber to produce silicone plugs.

-

Silicone Pad

Silicone pads have a shock absorbing effect and can effectively reduce damage from vibration and impact. Customized stamped silicone pads or custom molded silicone pads are becoming the choice for the electronics, machinery and transportation industries, and help to extend the life of equipment and improve work efficiency. The anti-slip properties of silicone pads can be used in a variety of applications such as non-slip pads, workbench pads and sports equipment. This increases safety and reduces the risk of accidents.

-

Silicone Rubber Bushing

Silicone rubber bushings are used to fill the gaps between objects, making them close and reducing wear between objects. Silicone rubber bushings are also used as intermediary materials for mechanical parts. Jan Huei provides customized silicone rubber bushings by compression moldings, such as rubber waterproof bushings for plumbing engineering, with a diameter of 150mm and a height of 50mm. It is made of Ethylene Propylene Diene Monomer (EPDM), which is good at weather resistance, chemical resistance, heat resistance, abrasion resistance, water resistance, anti-ozone, and UV-cut. The product is suitable for outdoor use.

-

Customized Silicone Parts of Swimming Goggle

Customized silicone goggles and silicone swimming accessories are used in silicone which is a popular material in sports accessories. We have been successfully producing this silicone swimming accessory according to the customer's picture and our professional compression molding and injection molding technology. In addition to providing professional process technology, Jun Huei can also provide professional advice for customers in the selection of materials. In this way, silicone swimming accessories is required long-term contact with the skin, so they are made of silicone with better antibacterial and elastic properties. Materials also comply with REACH and RoHS compliance. In response to market demand, we can provide multi-color production to diversify product performance. The minimum order quantity for each color is about 1,000.

-

Customized Silicone Fasteners

Silicone fasteners are not only fixing tools, but also adjustable in size. Through silicone molding technology, we ensure the stability and versatility of customized silicone fasteners by combining silicone with different materials to suit different usage environments and special needs. This technology enhances the structure and hardness of customized silicone fasteners. Our custom silicone fasteners are used in a wide range of applications, such as silicone straps to secure masks and adjust the length of silicone watch bands, as well as adjusting the size of silicone collars for pets and silicone feet to indicate the status of animals. These silicone fasteners not only provide excellent fastening properties, but also offer customers flexibility to ensure that every need is met.

-

Customized Silicone Holder

Silicone-coated stainless steel technology can custom silicone mobile phone holders, which the mold needs special development conditions, the technology is complicated and the finished product needs to comply with RoHS specifications. The customer trusts us and cooperates with us to develop customized silicone phone holders. With professional compression technology and customized capabilities, Jan Huei is committed to providing customers with a combination of different materials (stainless steel and silicone).

-

Customized Silicone Bracelet, Silicone Necklace

Jan-Huei's silicone bracelet tooling is used to produce silicone bracelets, which are custom printed to meet mass production requirements. The cost-effective production of silicone bracelets through tooling and customized printing brings several advantages to our customers. First of all, by using the public version of silicone bracelet tooling, customers can save a lot of time and cost in developing new silicone bracelet tooling. Customers can quickly turn their designs into actual finished silicone bracelets, saving them the waiting time and uncertainty associated with developing silicone bracelets. Secondly, Jan-Huei's customized printing service enables you to add brand logo and text on the silicone bracelet. This can be used by companies to promote their products, brands or events, such as silicone bracelets for marketing and promotional purposes.